Myomatrix Electrodes: Design and Specifications

Our microfabrication process yields flexible high-density electrode arrays with low impedance enabling researchers to record motor activity with resolution as high as single motor units in freely behaving animals and from a range of species including mice, rats, songbirds, and non-human primates. The arrays come in a variety of configurations designed for use in acute and chronic recording paradigms.

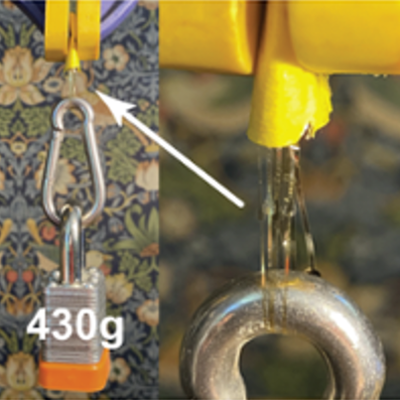

As illustrated in the short video clip, these arrays are both LIGHTWEIGHT and FLEXIBLE. The Omnetics connector is being held by forceps (upper right) and the tethered butterfly's wings generate a breeze that moves the array threads. As illustrated by the image, these arrays are also STRONG. The array threads have enough tensile strength to suspend the carabiner and the 430g lock.

General recording setup

Myomatrix arrays record muscle activity at motor unit resolution.

The nervous system controls behavior via motor units, each consisting of a single motor neuron and the muscle fibers it innervates. Each motor neuron’s spiking evokes motor unit action potentials in the corresponding muscle fibers. Myomatrix arrays bearing 32 electrode contacts on a flexible substrate can be targeted to one or more muscles and yield high-resolution recordings of motor activity during free behavior. Motor neurons, muscle fibers, and electrode arrays are not shown to scale. (Adapted from Fig. 1 in Chung et al., 2023)

Click here for information about the different array configurations

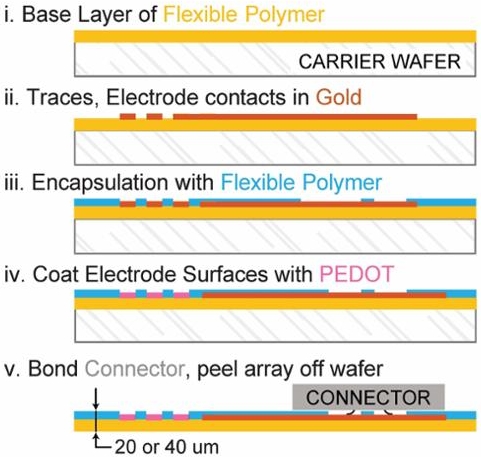

Overview of electrode array fabrication

Layers of insulating polymer (polyimide) and conductive metal (gold) are successively deposited on a carrier wafer to form a flexible, 20 or 40 μm thick electrode array of gold electrode contacts, which receive a surface treatment of PEDOT to improve recording properties. Electrodes are connected via thin gold traces to a receiving pad for a high-density connector (Omnetics Inc.) which is then bonded to the array. The completed array is then peeled off the carrier wafer. (Adapted from Supplemental Fig. 1 in Chung et al., 2023)